[Accurate, Spectra, India]

[Thor 3D Scanner, Calibry Mini, ROK]

Located at: CRF Annexe - G06

About:

Reverse engineering refers to the method of working backward from a product or system's final form to evaluate and understand its design, structure, and functionality.Through such a methodology, one can decode the product hierarchy getting an insight into the final details of the product ,may it be a physical product or software system.

Reverse engineering also helps in understanding the functional details of a system at micro level and develop alternate or better design without destructing its worthiness or efficiency .Going by the part history ,reverse engineering played a phenomenal role during Second World war .The several captured military weapons and armory were decoded through Reverse engineering by enemy counties for their own advantage

Objective:

The primary objective of a prototyping lab is to accelerate the development and testing of prototypes. This involves quickly creating and iterating on designs to identify and solve issues early in the product development process. Here are some key goals

⮚ Speed and Efficiency: Rapid prototyping labs aim to streamline the iteration process, making it faster and more cost-effective than traditional methods

⮚ Problem Solving: By quickly creating and testing prototypes, teams can identify design flaws and make necessary adjustments early

⮚ Collaboration: These labs often serve as hubs for cross-disciplinary collaboration, bringing together experts from various fields to work on innovative solutions

⮚ Innovation: Rapid prototyping encourages creative problem-solving and experimentation, leading to the development of novel products and technologies

Facilities Available:

Our facility has a coordinate measuring machine and a 3D scanner.

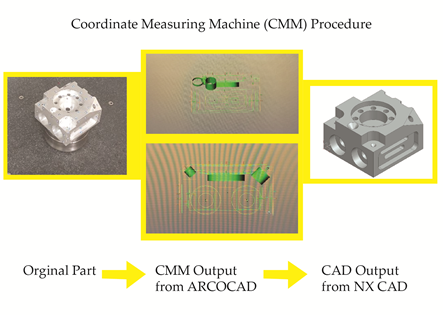

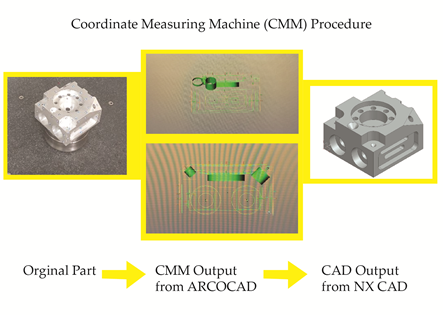

◆ Coordinate Measuring Machine (CMM)

One of the most popular types of coordinate measuring devices is the Bridge CMM.This CMM are characterized by high precision and low measurement deviations even in production-related applications

Feature of Bridge CMM

Proven design with all granite construction for stable performance, Wrap around air bearing construction for high acceleration and stability

Zero hysteresis belt drive for smooth repeatable movement

X & Z axis guide ways made hollow reducing mass to achieve high acceleration

In built Y axis for better homogeneity of material

High resolution Reader Head for better accuracy

Hardware Details

Model: Spectra

Machine Make: Accurate

Controller Make: Renishaw, UK

Measuring Range:

• X Axis: 800mm,

• Y Axis: 1000mm,

• Z Axis: 600mm

Measuring Accuracy: 2.2+L/350µm

Repeatability: 0.002mm

Probe Head :Renishaw PH10 -PAA1 TP20

Module Head Range: 0.50mm to 100mm

Table Material: Granite

Power Supply: 230VAC, 50/60Hz, 1.4KW

Software Details

Controller Software: UCC Server

Interface Software: ARCOCAD

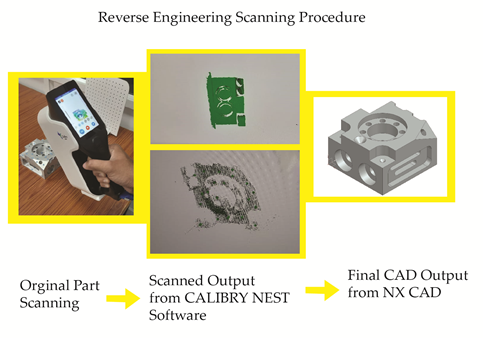

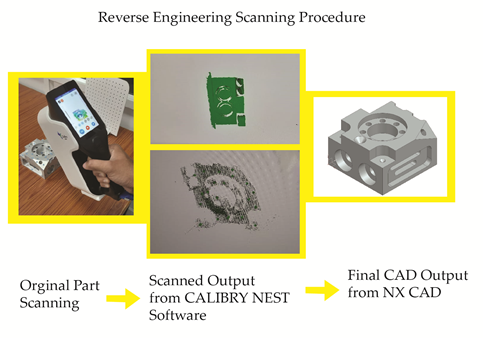

◆ 3D Scanner

Calibry Mini is a hand-held 3D scanner designed to digitize small objects Ranging from 2 cm to 30 cm in length. Blue LED lights ensure high quality of captured data and built-in touchscreen makes scanning easier. The device is lightweight, dependable, and simple to handle.

Hardware Details

Model: Thor 3D

Machine Make: Calibry Mini

Accuracy: Up to 0.07 mm

Accuracy over distance: Up to 0.1 mm over 1 m

Point resolution: Up to 0.15 mm

Depth of view: 180-300 mm

Field of view: Min 86x115 mm to Max 144x192 mm

Texture: Yes

Frame Rate: 25-30 fps

Data Acquisition speed Up to 3M points/sec

Multi-core processing: Yes

Weight: 900 grams

Touchscreen: Yes, 4inch

Operating temperature: +5 / +40C

Software Details

Controller and Interface Software: Calibry Nest

Reverse engineering application:

CMM:

3D Scanner:

Courses:

1. Introduction to CMM (80 Hrs)

2. Introduction to 3D Scanner (40 Hrs)

3. Advance Course on Prototyping (100 Hrs)

Fees Structure:

| Details |

Duration |

Charges* |

| UG/PG |

1 Month |

Rs. 2500/- |

| 2 Month |

Rs. 3500/- |

| 3-4 Month |

Rs. 5000/- |

| Diploma |

3-4 Month |

Rs. 5000/- |

| 10th / 11th / 12th / ITI |

1 Month |

Rs. 1000/- |

| Faculty Development |

|

Rs. 3000/- |

| Industrial Personnel |

|

Rs. 5000/- |

*GST(18%) extra.

For further Query Contact:

Mr. Royston Fernandes, phone: +91-7892451600 / +91-9535423533, email: coemech@nitk.edu.in

Office-CRF, email: office.crf@nitk.edu.in