[NX CAD, Siemens, Germany]

Located at: CRF Annexe -S08

About:

Participants can learn more about product design and development, including innovation using push and pull technology approaches, with the help of the Product Design and Development Lab.

Also, they can learn about finalizing the design and manufacture of the product. Staring with a product roadmap, attempt is made towards maximizing the product performance, developing a prototype and then testing the product in action.

Objective:

The lab's goal is to familiarize students with the practical aspects of developing a product as an embodiment of a collection of cohesive parts that fulfill a list of specified functions that the product must possess. The lab's main goal is to teach product design.

A well-designed product can increase a product's marketability by lowering production costs, increasing the product's quality, making it easier to operate or use, and/or improving its appearance. Sometimes a product's unique design is the only thing that makes it stand out from the competition.

Facility:

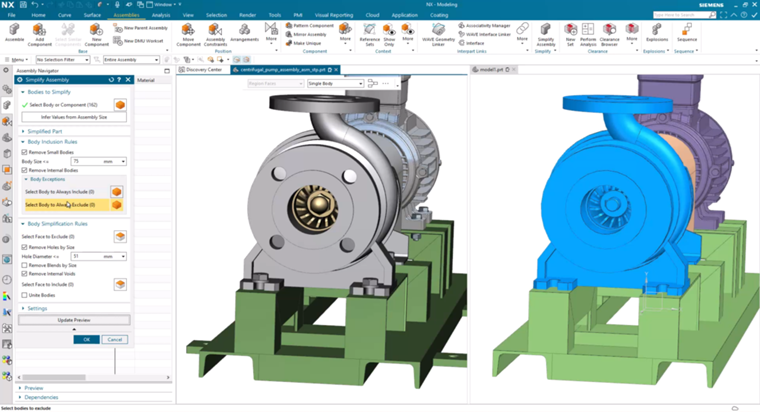

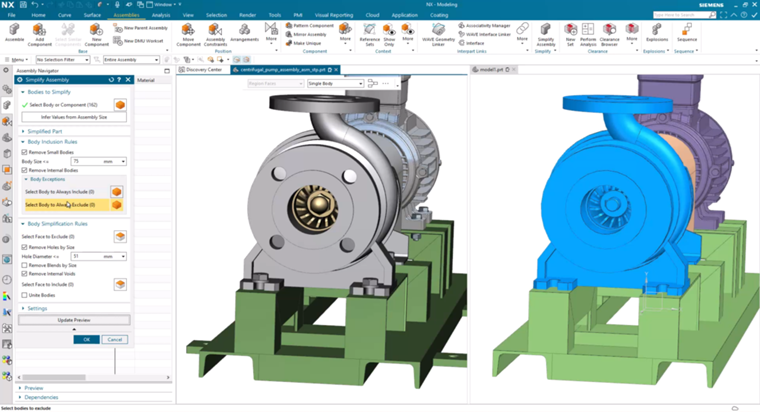

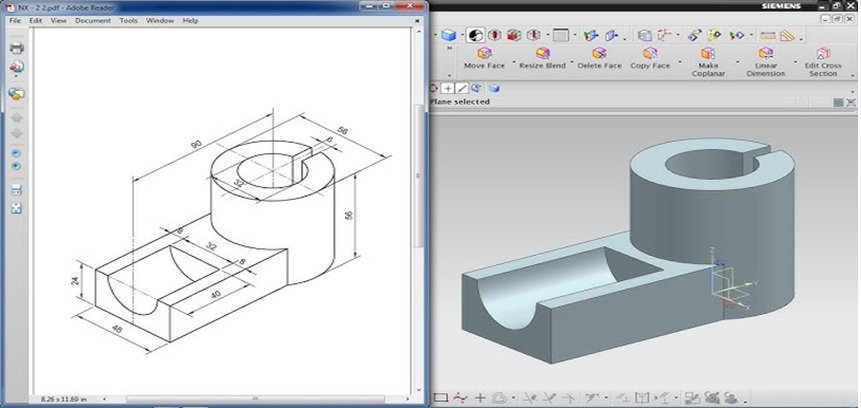

This Laboratory involves seamless application of CAD-CAE-CAM through NX platform running through life cycle model.

Product Design and Validation Lab introduces to the following Modules using NX- CAD, NX CAE.

Basic Design, Modeling, Drafting, Sheet Metal Design, Assembly and Industrials Design, Advanced Simulation Process and Solution.

Basic Part Modelling, Assembly, Surface Modeling, Sheet Metal and Drafting.

Specification:

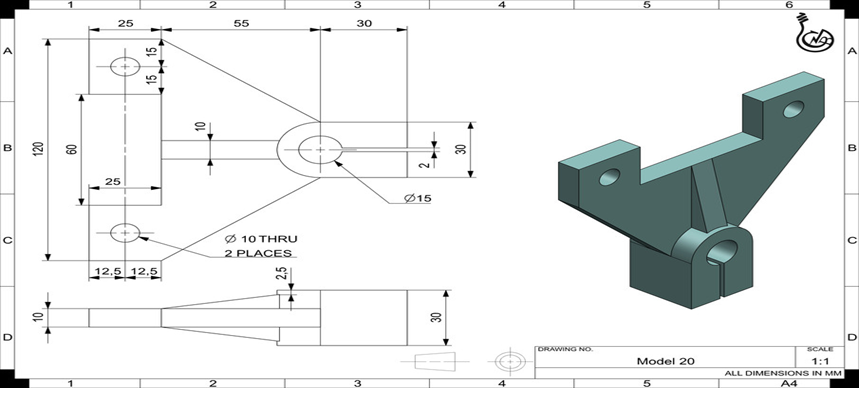

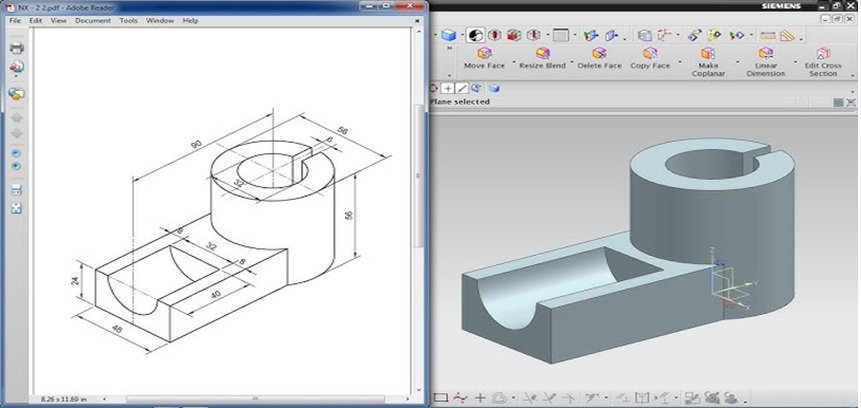

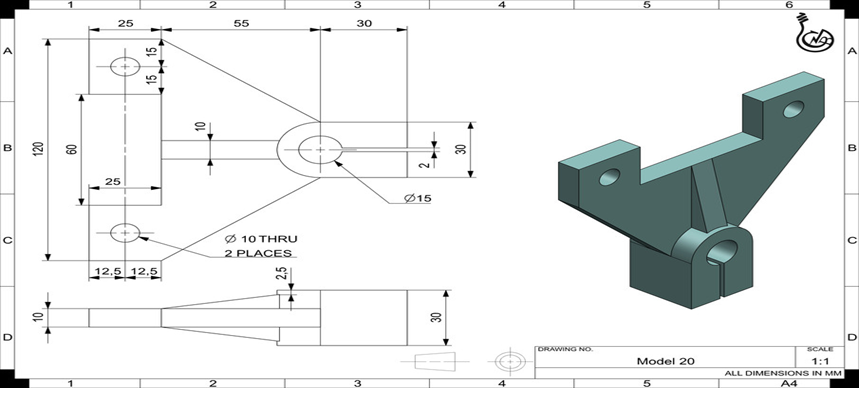

1. Part Modelling:

In Part Modelling a Feature is defined as the smallest building block that can be modified individually.

In NX CAD, the solid models are created by integrating a number of these building blocks.

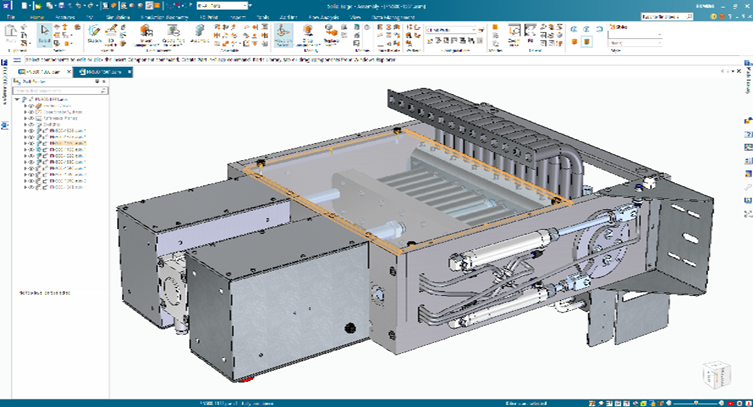

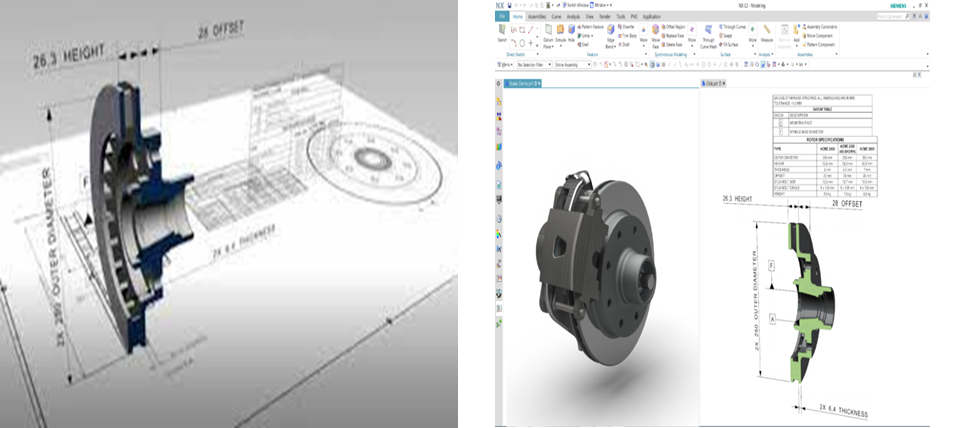

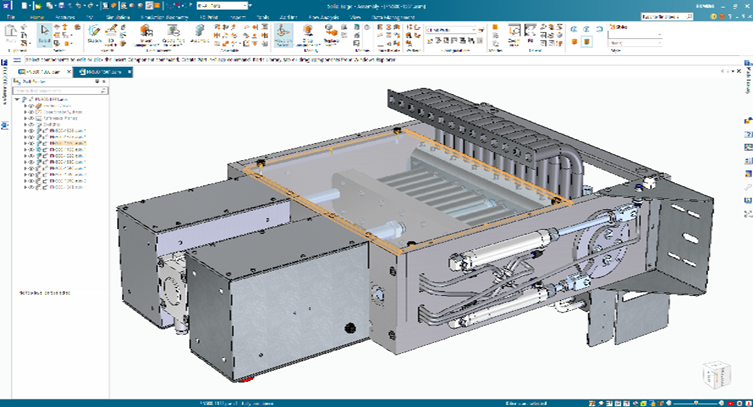

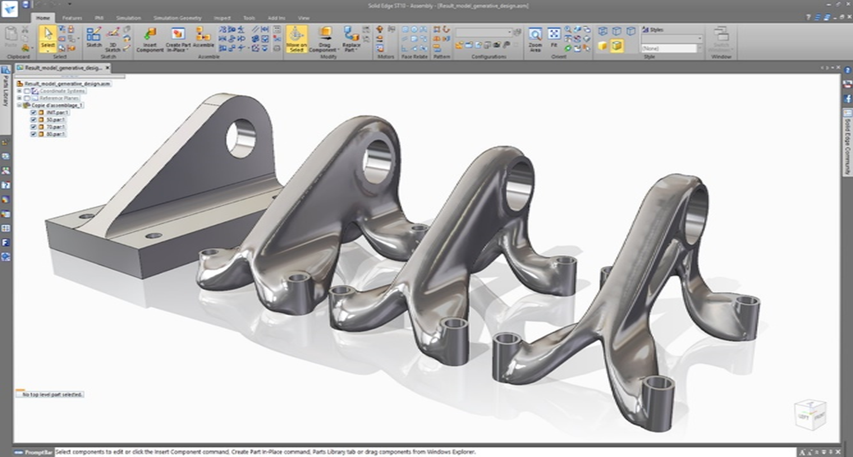

2. Assembly:

An assembly design consists of two or more components assembled at their respective work positions by using parametric relations.

Top-Down Assembly

In the top-down assembly design approach, the components are created in the same assembly document and can be saved within the assembly or as separate part files.

Bottom-up Assembly

In this assembly design approach, all components are created as separate part documents, and then they are placed and referenced in the assembly as external components.

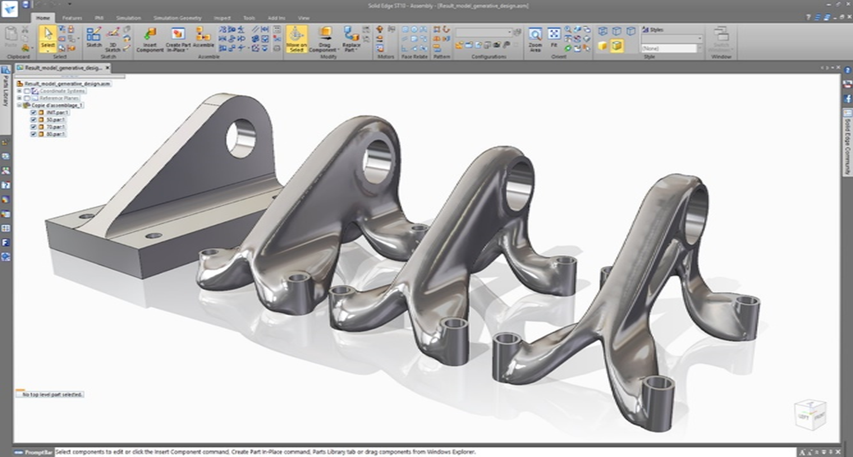

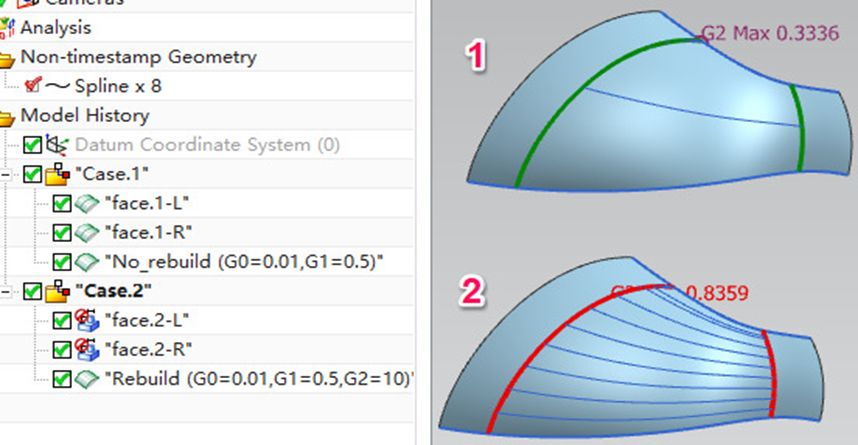

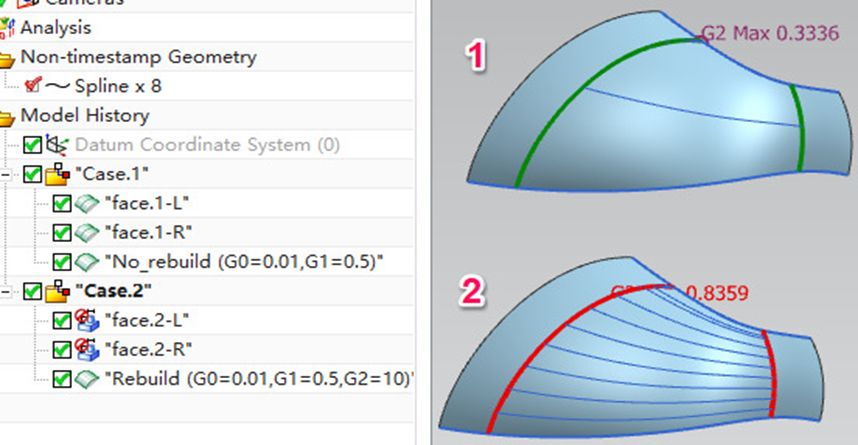

3. Surface Modelling:

Surface modelling is the process of creating surfaces. It can be applied to impart realistic textures, portray smoothness, and highlight flaws. Surface models are three-dimensional and viewable from any angle. Although surface modelling techniques can be used alone to build a model, they are usually combined with solid modelling.

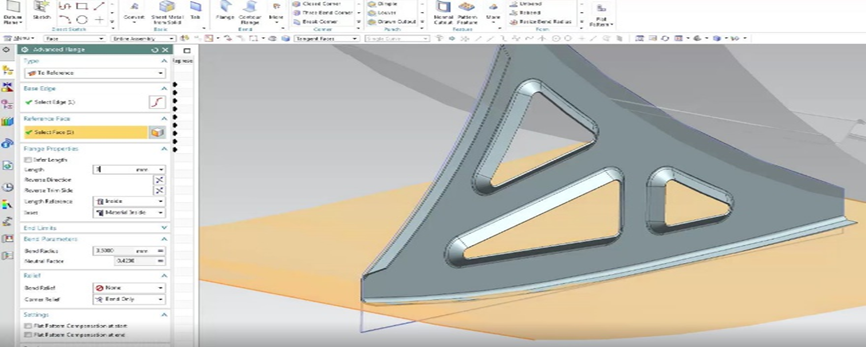

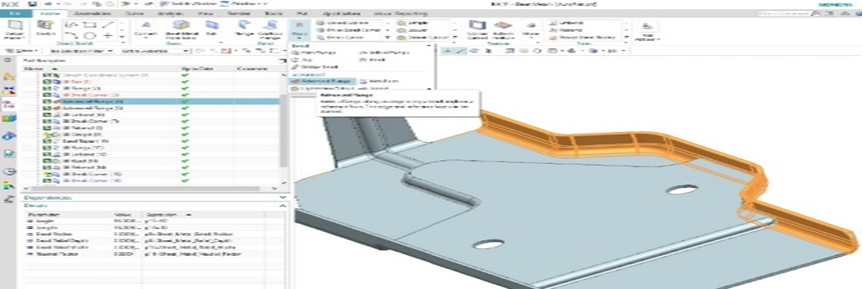

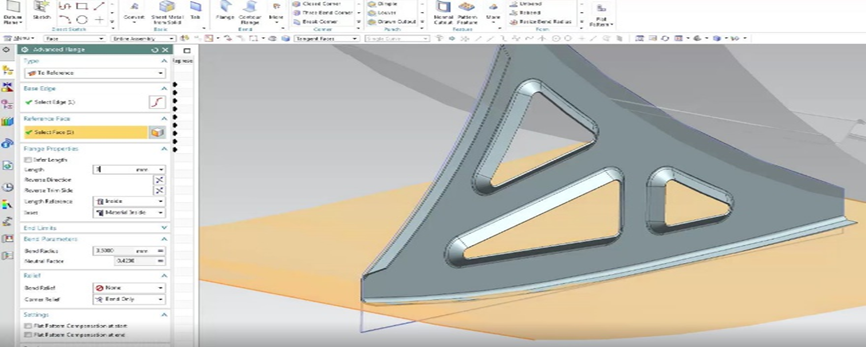

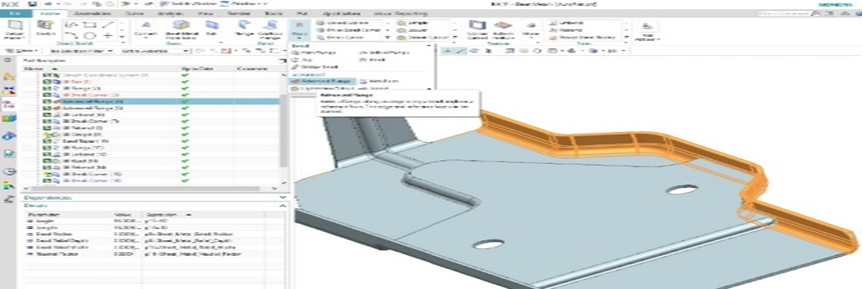

4. Sheet Metal Modelling:

The process of cutting, bending, punching, and assembling flat sheets of different kinds of metal into desired structures or products is known as sheet metal fabrication. NX Siemens help with sheet metal work design.

Involves creating the sheet metal components that are commonly seen in airframes, such as the interior airframe structures and support ribs and brackets that are fastened to the exterior and inner mould line surfaces. Usually, these nonlinear airframe components are break-formed or hydro-pressed.

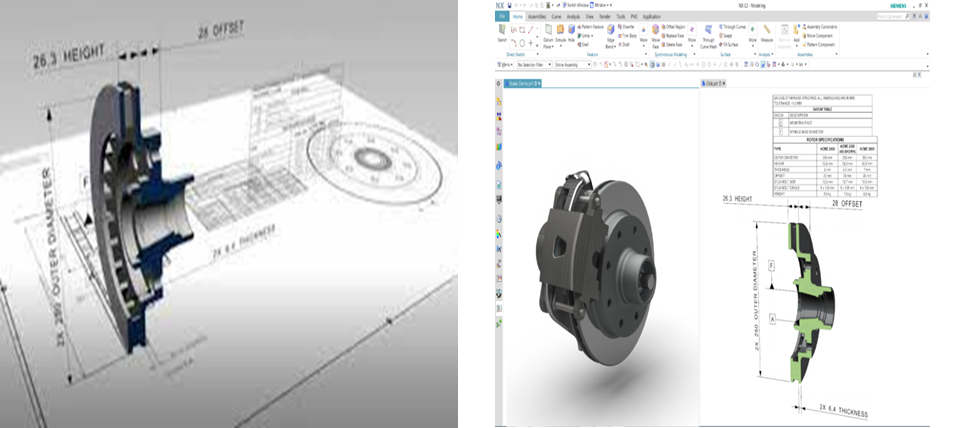

5. Drafting:

Computer-aided design (CAD) is the use of computer programs to create, modify, analyse and document two- or three-dimensional (2D or 3D) graphical representations of physical objects as an alternative to manual drafts and product prototypes.

NXCAD is a mechanical product design solution developed by Siemens that helps companies boost product design efficiency and quality.

Application:

• Product Design Engineer: Using NX CAD software to create 3D product design and generate CAM instructions for prototypes and production.

• Product Development Manager: Managing a team of engineers, and ensuring the effective use of NX CAD, and CAM tools to meet project goals.

• CAD/CAM Technician: Utilizing NX software to create detailed 3D models, generate toolpath instructions for machining.

• Manufacturing Engineer: Applying CAM basics with NX -CAM to optimize manufacturing processes, create machining programs, and ensure efficient production.

Courses:

1. Certificate course on “Basic CAD Design using NX CAD” (40Hrs)

2. Certificate course on “Product Design Fundamentals” (40Hrs)

3. Certificate course on “Design in context of an assembly” (40Hrs)

4. Certificate course on “Surface Modelling using NX CAD” (40Hrs)

5. Certificate course on “Sheet Metal Design Using NX CAD” (40Hrs)

6. Certificate course on “Advanced CAD Modelling with NX CAD” (150Hrs)

Fees Structure:

| Details |

Duration |

Charges* |

| UG/PG |

1 Month |

Rs. 2500/- |

| 2 Month |

Rs. 3500/- |

| 3-4 Month |

Rs. 5000/- |

| Diploma |

3-4 Month |

Rs. 5000/- |

| 10th / 11th / 12th / ITI |

1 Month |

Rs. 1000/- |

| Faculty Development |

|

Rs. 3000/- |

| Industrial Personnel |

|

Rs. 5000/- |

*GST(18%) extra.

For further Query Contact:

Mr. Royston Fernandes, phone: +91-7892451600 / +91-9535423533, email: coemech@nitk.edu.in

Office-CRF, email: office.crf@nitk.edu.in