Mechatronics Lab

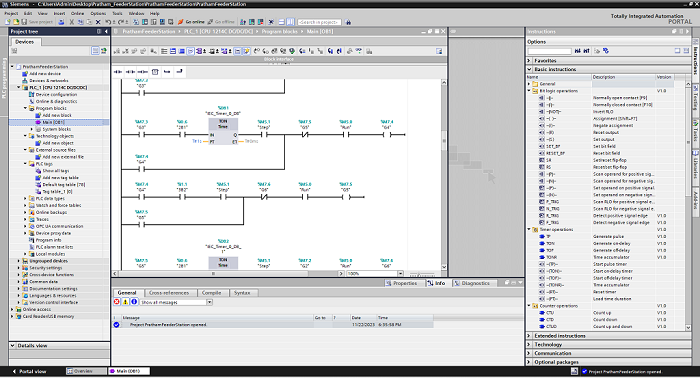

[TIA Portal, Siemens, Germany]

Located at: CRF Annexe - S05

About:

Mechatronics is the fundamental building block in multiple engineering disciplines. This lab provides a platform to foster knowledge and working experience of synergistic integration of diverse engineering disciplines.

Objectives:

⮚ To encourage industry-driven innovation and cross-disciplinary study in the forefront areas of mechatronics

⮚ Providing learners an individualized lab where they can apply mechatronics fundamentals

⮚ To offer an environment where students can conduct experimental research on basic sequence control by changing programing logic

⮚ The lab is set up to help students gain ladder logic programing skills, with a variety of sensors and actuators

Mechatronics Facilities:

• Advanced Mechatronics modular systems and specially compiled with Siemens S7-1200 PLC kit

• Janatics make Pneumatic valve and actuator

• Hands on learning on working and programming of Mechatronics Modular System

• Troubleshooting with interpretation of process circuit diagram and data sheet

• Development of projects and research based on real time industrial problems

This lab comprises of advanced Mechatronics modular station specially compiled with Siemens PLC and Janatic valve and Actuator.

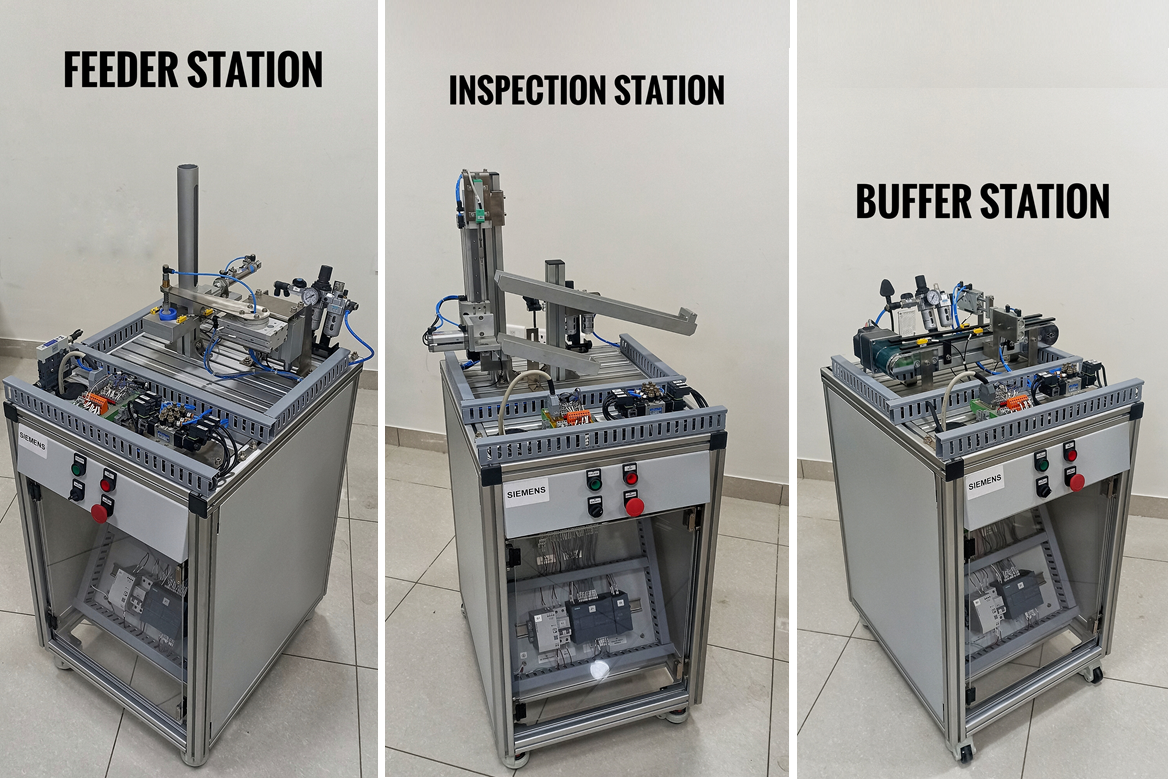

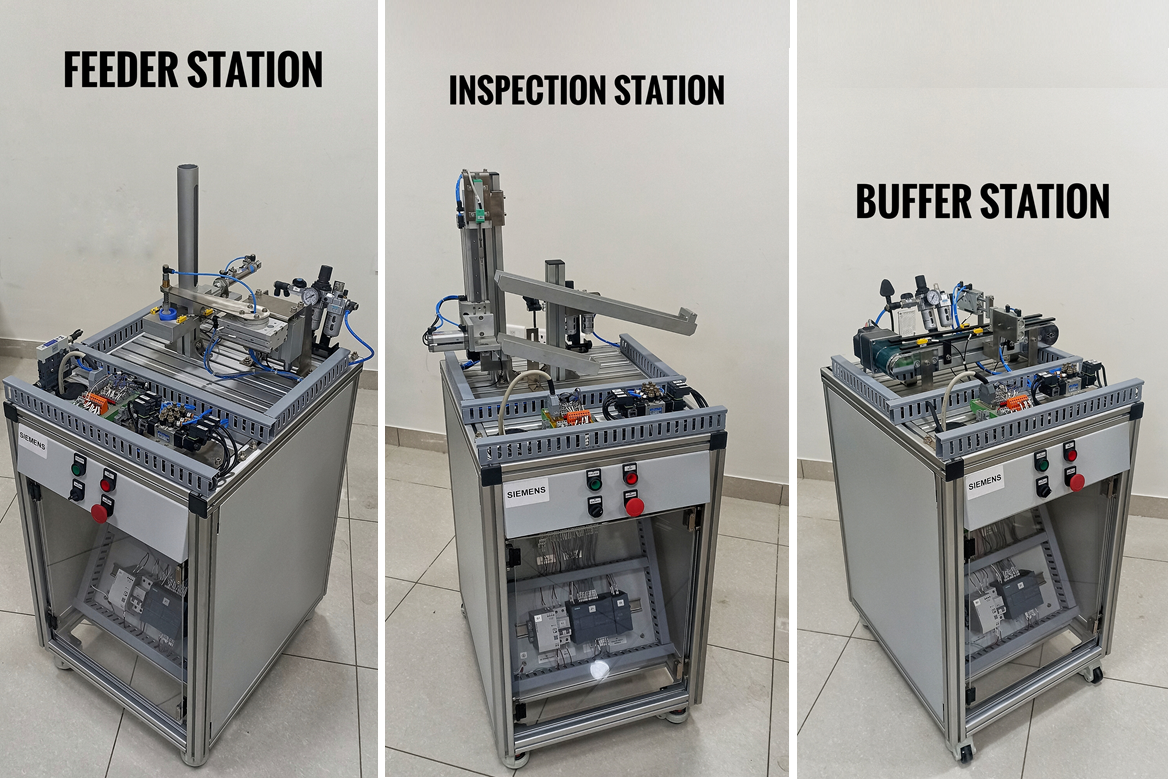

*Feeder Station: This station separates the component from the magazine and distributes the components one by one via rotary pick and place module for further processing, with the help of vacuum cup, pneumatic cylinder and rotary actuator. For feedback of cylinders reed switch, through beam sensor output is given to PLC input and output of PLC is connected to various direction control valves to control pneumatic cylinders and actuators.

*Inspection Station: Here the received part from the loader station is inspected, the height of the given component is measure using linear transducer, if height is according to given, it is feed to down stream process else rejected to scrap rack. Irrespective to component material it checks the height of the part.

*Buffer Station: This ensure steady flow of component to the process station by allowing one component at a time for processing. It can store up to 5 part pieces. It is used to control the part flow between inspection station to down steam station by using various sensor and PLC S7-1200PLC.

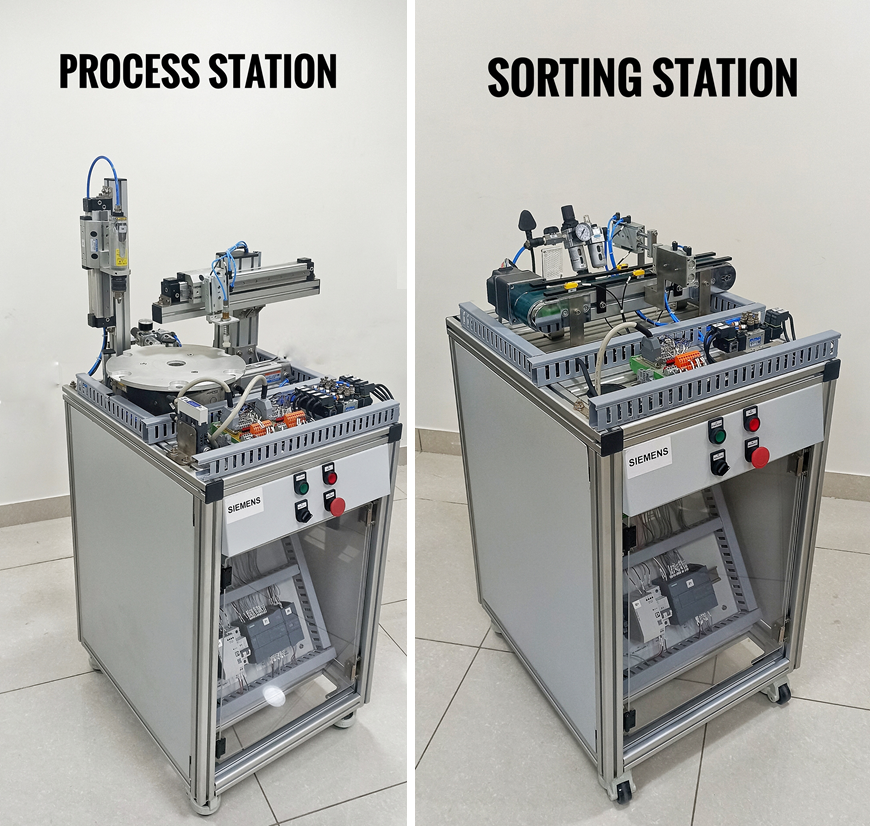

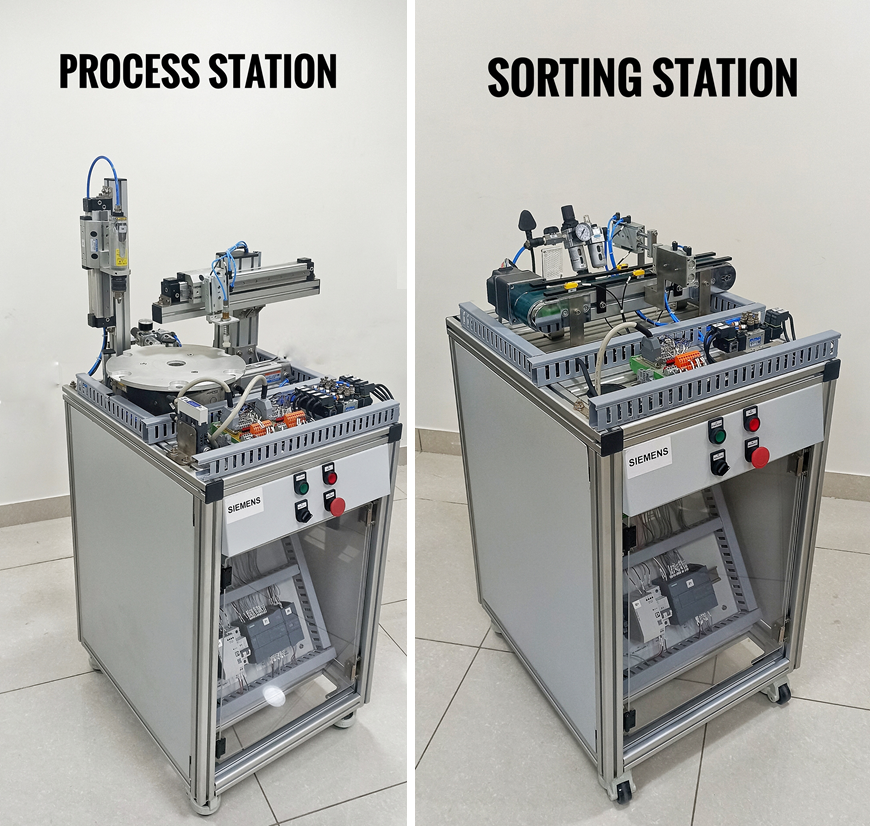

*Process Station: The process station performs machining operations like drilling, stamping etc, on a pneumatic driven rotary indexing table and transfers the work via pick and place module to downstream station

*Sorting Station: This station sorts incoming work piece based on color and materiel characteristics to appropriate slide. This station has 3 slides to sort the different materials and color of jobs that are arriving at this station. The sensor senses various parts respectively and the actuator separates the parts with the help of PLC.

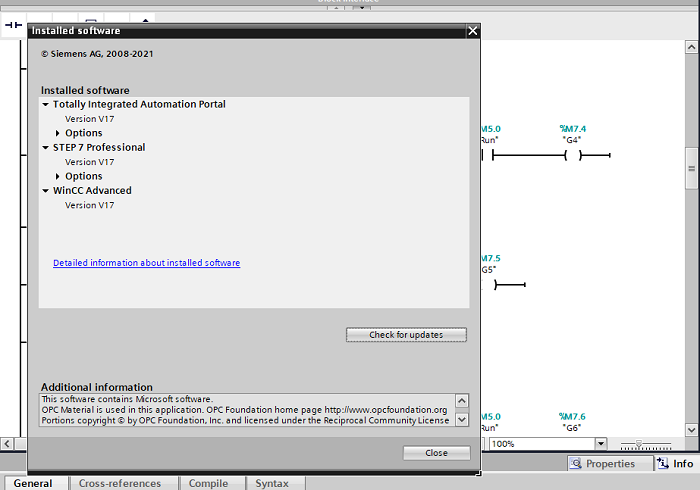

Software used to Program Siemens PLC-S7-1200 TIA Portal V17

Interface

Configuration

Application:

• Industrial exposure

• Troubleshooting in machine failure

• Hands on PLC programming

• Understanding Electrical diagram

• Knowledge on sensor and actuator at industrial level

About Equipments:

• Machine make - Siemens

• PLC make - Siemens (S7-1200) Germany

• Pneumatic Valve and Actuator - Janatics India

• Software - TIA Portal v17 (STEP-7 Professional)

• Sensor make - Banner and Sick

Courses:

Certification course on “Fundamentals of Mechatronics” (80Hrs)

Fees Structure:

| Details |

Duration |

Charges* |

| UG/PG |

1 Month |

Rs. 2500/- |

| 2 Month |

Rs. 3500/- |

| 3-4 Month |

Rs. 5000/- |

| Diploma |

3-4 Month |

Rs. 5000/- |

| 10th / 11th / 12th / ITI |

1 Month |

Rs. 1000/- |

| Faculty Development Program |

|

Rs. 3000/- |

| Industrial Personnel |

|

Rs. 5000/- |

*GST(18%) extra.

For further Query Contact:

Mr. Royston Fernandes, phone: +91-7892451600 / +91-9535423533, email: coemech@nitk.edu.in

Office-CRF, email: office.crf@nitk.edu.in