Factory Automation Lab

[Siemens, Germany]

Located at: CRF Annexe- S06

About:

Automation Lab is a high-level advanced automation tool used to control complex process plants. The functional distribution makes this tool promising for the implementation of advanced control strategies. Many industries are using this control system to fully automate their plants.

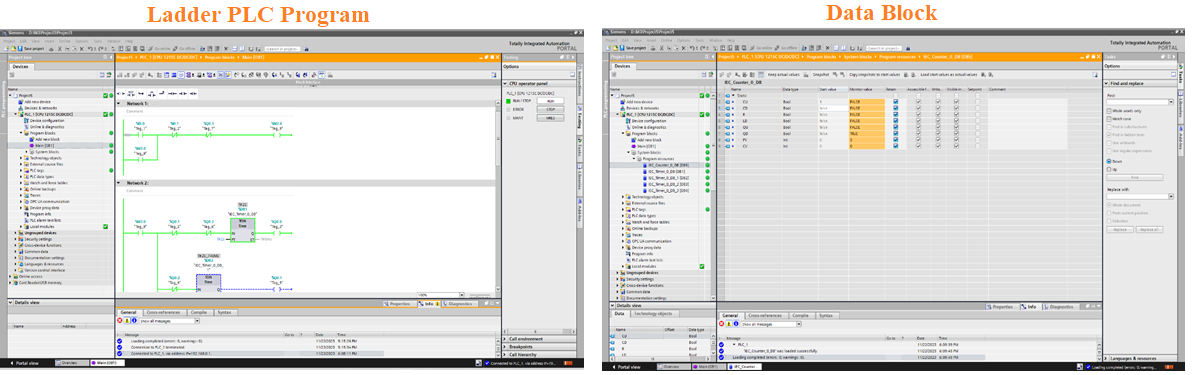

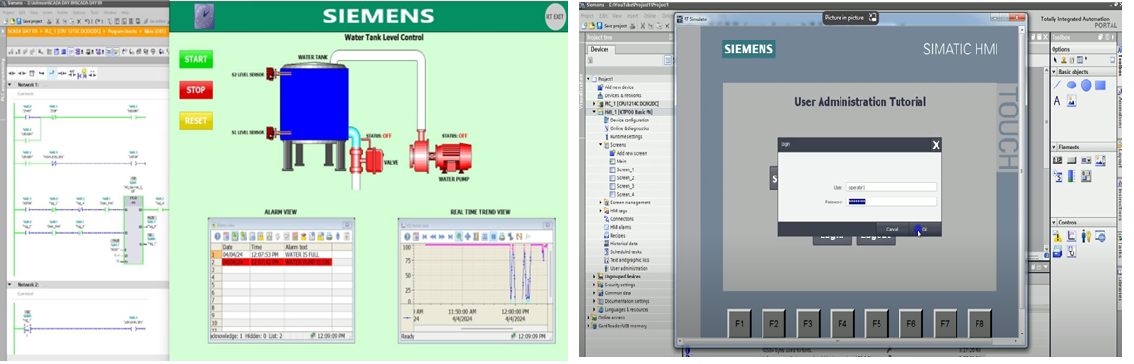

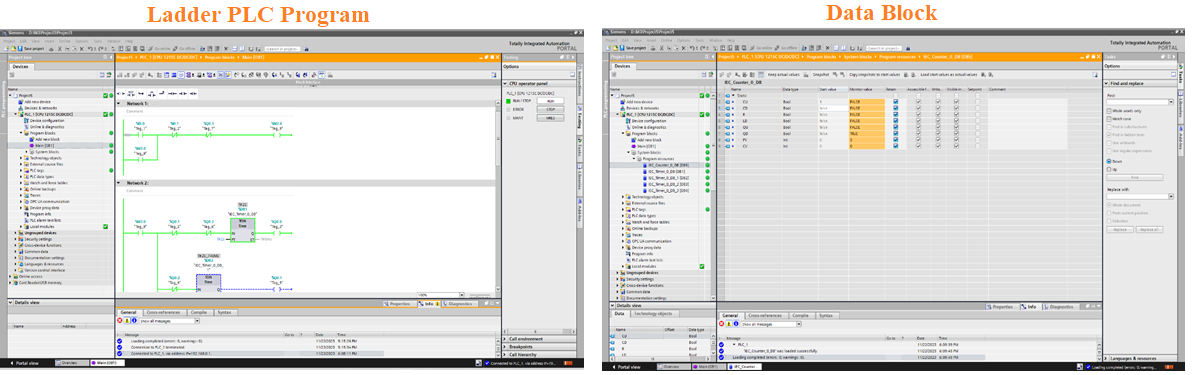

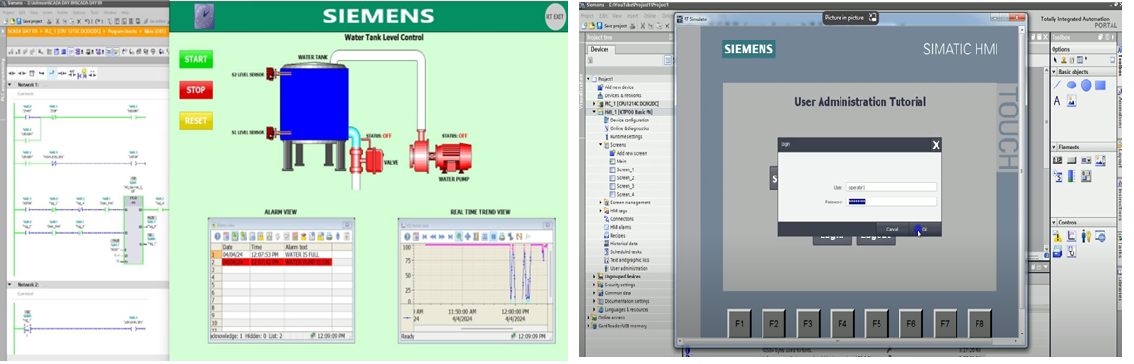

The complex controls demand a different kind of thought process to implement automation philosophies. This laboratory gives students insight into 'Ladder Logic’ programming , Human Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA).

Objective:

⮚ Identify the requirements of automation in a process plant

⮚ Develop various control schemes using Ladder Logic Programming

⮚ Troubleshoot the program implemented for a plant using Ladder Logic

⮚ To develop new technologies applicable to Industry 4.0

⮚ To enhance the scope of employment

Facility available:

Industrial Controller has become on integral part of digital manufacturing resulting fully automated factory setup with higher degree of flexibility. PLC is a Programmable logic Controller working on binary signal. It receives input from field and updates/triggers the output by executing relevant the program which is present in memory. It performs logical, sequential, timing, counting and arithmetic operations in the case of its program execution. Based on the signal received from filed sensors, output are triggered by invoking relevant program residing in the system memory.

1. S7-1200 PLC Training Kit:

Specification

SIMATIC S7-1200- CPU 1215C compact CPU, DC/DC/DC, 2 PROFINET ports, onboard I/O: 14 DI 24 V DC; 10 DO 24V DC; 0.5A; 2 AI 0-10 V DC, 2 AO 0-20 mA DC, Power supply: 20.4-28.8VDC, Memory 125KB

2. S7-1500 PLC Training Kit:

Specification

Central processing unit with 1 MB work memory for program and 5 MB for data, 1st interface: PROFINET IRT with 2-port switch, 2nd interface: PROFINET RT, 3rd interface: PROFIBUS, 10 n bit performance, SIMATIC Memory Card required.

PLC SOFTWARE- TIA PORTAL S7 -Professional

• HMI and SCADA

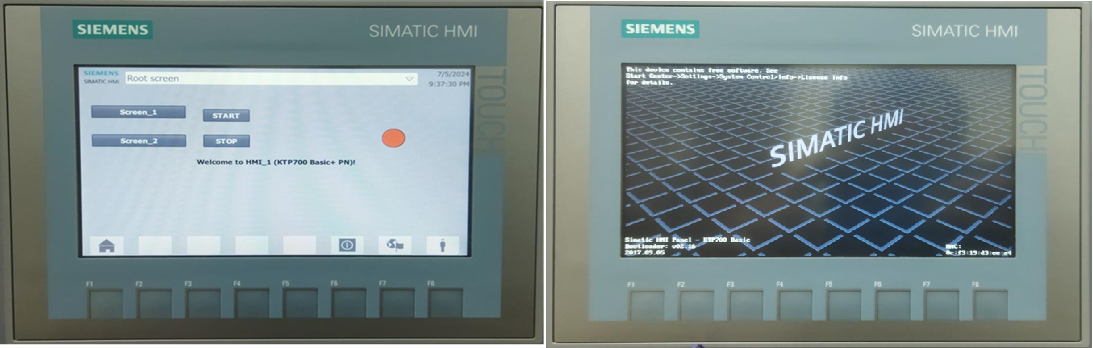

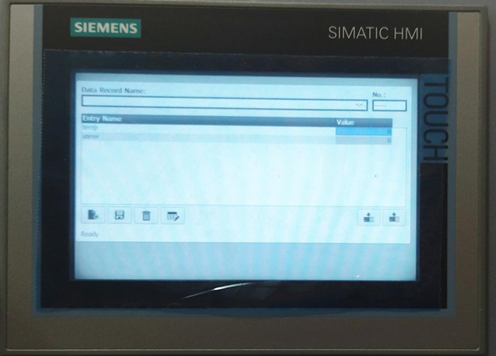

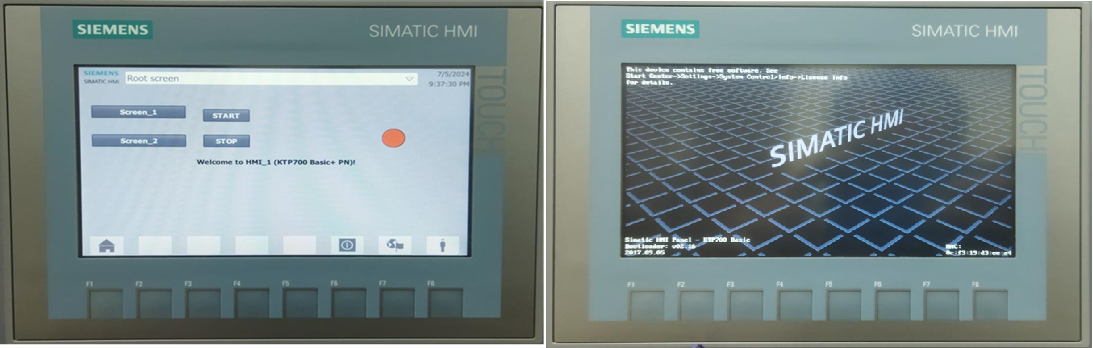

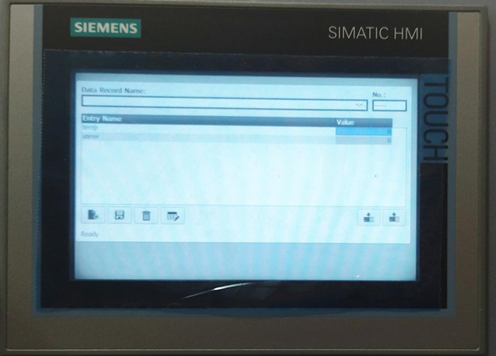

A HMI/SCADA is a category of software-based control system architecture that relies on networked data. A graphical user interface allows the operator to feed the input and monitor the performance of many equipments and issue process commands. This can be accomplished through a user friendly graphical device.

• HMI SIMATIC BASIC PANEL- KTP700 Basic

7'' TFT display, 800 x 480 pixel, 64K colors; Key and Touch operation, 8 function keys; 1 x PROFINET, 1 x USB

• HMI SIMATIC COMFORT PANEL- TP700 Comfort

7.0'' TFT display, 800 x 480 pixels, 16M colors; Touch screen; 1 x MPI/PROFIBUS DP, 1 x PROFINET/Industrial Ethernet interface with MRP and RT/IRT support (2 Ports); 2 x Multimedia card slot; 3 x USB

• HMI and SCADA SOFTWARE- TIA PORTAL-WinCC RT Professional

Runtime software for PC-based SCADA systems: Standalone (needs WinCC Runtime Professional); Server (needs WinCC Runtime Professional and WinCC Server for Runtime Professional)

Factory Automation Application:

• Automation of industrial processes such as assembly, packaging, and inspection, and production plant.

• Online monitoring and controlling of operation in process plant.

• Control of electro-mechanical processes in reliable way.

• Food processing, Robotics, Power plant, etc.

Courses:

1. Certification course on “Basics of PLC (Programmable Logic Controller)” (50Hrs)

2. Certification course on “PLC and HMI (Human Machine Interface)” (80Hrs)

3. Certification on “PLC and SCADA” (80 Hrs)

4. Certification on “HMI and SCADA” (100 Hrs)

Fees Structure:

| Details |

Duration |

Charges* |

| UG/PG |

1 Month |

Rs. 2500/- |

| 2 Month |

Rs. 3500/- |

| 3-4 Month |

Rs. 5000/- |

| Diploma |

3-4 Month |

Rs. 5000/- |

| 10th / 11th / 12th / ITI |

1 Month |

Rs. 1000/- |

| Faculty Development Program |

|

Rs. 3000/- |

| Industrial Personnel |

|

Rs. 5000/- |

*GST(18%) extra.

For further Query Contact:

Mr. Royston Fernandes, phone: +91-7892451600 / +91-9535423533, email: coemech@nitk.edu.in

Office-CRF, email: office.crf@nitk.edu.in